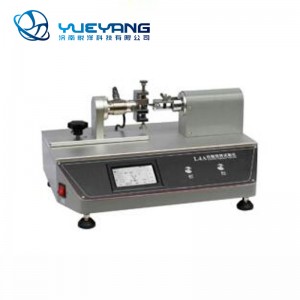

(Chaena) YY026H-250 Sesebelisoa sa ho Lekanya Matla a Tensile sa Elektroniki

Sesebelisoa sena ke tlhophiso e matla ea liteko indastering ea masela ea lehae ea mohlala oa ts'ebetso ea boemo bo holimo, e phethahetseng, e nepahetseng haholo, e tsitsitseng le e tšepahalang. E sebelisoa haholo liindastering tsa khoele, lesela, khatiso le daea, lesela, liaparo, zipper, letlalo, e seng lohiloeng, geotextile le tse ling tsa ho roba, ho hahola, ho roba, ho pebolla, ho roka, ho tenyetseha, le ho thothomela.

GB/T3923.1、GB/T3917.2-2009、GB/T3917.3-2009、GB/T3917.4-2009、GB/T3917.5-2009、GB/T13773.1-2008、FZ/T8000061.

1. Amohela mokhanni oa servo le enjene (taolo ea vector), nako ea karabelo ea enjene e khuts'oane, ha ho na lebelo le feteletseng, ketsahalo e sa lekanang ea lebelo.

2. E hlomelitsoe ka encoder bakeng sa taolo e nepahetseng ea ho beha le ho lelefatsa lisebelisoa.

3. E na le sensor e nepahetseng haholo, "STMicroelectronics" ST letoto la 32-bit MCU, sesebelisoa sa ho fetolela sa 24 A/D.

4. E na le sesebelisoa sa pneumatic, sekotwana se ka nkeloa sebaka, 'me se ka etsoa ka thepa ea bareki.

5. Sistimi e sebetsang ea Windows e tšehetsang software inthaneteng,

6. Sesebelisoa se tšehetsa taolo ea moamoheli le khomphutha ka mahlakore a mabeli.

7. Setaele sa dijithale sa software ya pele ho kgatello ya maikutlo.

8. Setaele sa dijithale sa bolelele ba sebaka, boemo ba othomathiki.

9.Tshireletso e Tloaelehileng: tshireletso ya switjha ya mechini, maeto a hodimo le a tlase a moedi, tshireletso ya ho feteletsa dintho, motlakase o feteletseng, motlakase o feteletseng, ho chesa haholo, motlakase o tlase, motlakase o tlase, tshireletso ya othomathiki ya ho dutla, tshireletso ya letsoho ya switjha ya tshohanyetso.

10. Khetho ea tlhoro ea teko ea ho tabola, ho khephoha le maemo a ho fumana qeto li ka beoa ke moreki.

11. Tekanyo ea boleng ba matla: Tekanyo ea khoutu ea dijithale (khoutu ea tumello), netefatso e bonolo ea sesebelisoa, ho nepahala ha taolo.

12. Moralo o tloaelehileng oa potoloho ea mochini kaofela, tlhokomelo le ntlafatso e bonolo ea lisebelisoa.

1. Software e tšehetsa sistimi e sebetsang ea Windows, ka tšohanyetso, e bonolo haholo, ntle le koetliso ea litsebi.

2. Software ea inthanete ea khomphutha e tšehetsa ts'ebetso ea Sechaena le Senyesemane.

3. Tiisa lenaneo la teko le tiisitsoeng ke mosebelisi, paramethara ka 'ngoe e na le boleng ba kamehla, mosebelisi a ka bo fetola.

4. Sebopeho sa ho beha diparamithara: nomoro ya thepa ya sampole, mmala, sehlopha, nomoro ya sampole le diparamithara tse ding di setwa ka boikemelo mme di hatiswa kapa di bolokwa ho tsona.

5. Mosebetsi oa ho atametsa le ho ntsha lintlha tse khethiloeng tsa mothapo oa teko. Tobetsa ntlha efe kapa efe ea ntlha ea teko ho bontša boleng ba ho tsitlella le ho lelefatsa.

6. Tlaleho ea lintlha tsa teko e ka fetoloa hore e be Excel, Word, jj., liphetho tsa liteko tsa ho beha leihlo ka boiketsetso, tse bonolo ho hokahana le software ea tsamaiso ea khoebo ea bareki.

7. Mothapo oa teko o bolokoa ho PC, e le hore ho tlalehuoe potso.

8. Software ea teko e kenyelletsa mekhoa e fapaneng ea teko ea matla a thepa, e le hore teko e be bonolo haholoanyane, e potlake, e nepahetse ebile e sebetsa ka litšenyehelo tse tlase.

9. Karolo e khethiloeng ea mothapo e ka atametsoa le ho theoloa ka boithatelo nakong ea teko.

10. Mokoloko oa sampole o lekiloeng o ka bontšoa tlalehong e tšoanang le sephetho sa teko.

11. Mosebetsi oa lintlha tsa lipalo-palo, e leng ho bala data e lekoteng le lekantsoeng, o ka fana ka kakaretso ea lihlopha tse 20 tsa data, 'me oa fumana bolelele bo tsamaellanang kapa boleng ba matla ho latela boleng bo fapaneng ba matla kapa tlhahiso ea bolelele ke basebelisi.

15. Mosebetsi oa ho beha maemo a mangata a kobehileng.

16. Diyuniti tsa teko di ka fetolwa ka tsela e sa reroang, jwalo ka Newton, diponto, matla a kilogram le tse ding.

17. Mosebetsi oa tlhahlobo ea software: ntlha ea ho robeha, ntlha ea ho robeha, ntlha ea khatello, ntlha ea chai, modulus ea pele, phetoho ea elastic, phetoho ea polasetiki, jj.

18. Theknoloji e ikhethang (ea moamoheli, ea khomphutha) ea taolo ea mahlakore a mabeli, e le hore teko e be bonolo le e potlakileng, liphetho tsa liteko li ruile ebile lia fapana (litlaleho tsa data, li-curve, li-graph, litlaleho).

1. Boleng ba sebaka le indexing: 2500N, 0.1N;

2. Qeto ea boleng ba matla 1/60000

3. Ho nepahala ha sensor ea matla: ≤±0.05%F·S

4. Ho nepahala ha mojaro oa mochini: mefuta e felletseng ea 2% ~ 100% ho nepahala ha ntlha efe kapa efe ≤±0.1%, kereiti: boemo ba 1

5. Mefuta ea phetoho ea lebelo la mahlaseli (ho ea holimo, tlase, taolo ea lebelo, lebelo le tsitsitseng) :(10 ~ 500) mm/min (ka har'a mefuta ea tlhophiso e lokolohileng)

6. Stroke e sebetsang hantle: 800mm

7. Qeto ea ho falla: 0.01mm

8. Sebaka se fokolang sa ho khomarela: 10mm

9. Mokhoa oa ho beha sebaka ka ho khomarela: tlhophiso ea dijithale, boemo ba othomathiki

10. Bophara ba gantry: 360mm

11. Phetoho ea yuniti: N, CN, IB, IN

12. Polokelo ea data (karolo ea moamoheli): ≥ lihlopha tse 2000

13. Phepelo ea motlakase: 220V, 50HZ, 1000W

14. Boholo ba kantle: 800mm×600mm×2000mm (L×W×H)

15. Boima: 220kg

1. Moamoheli--- Sete e le 1

2. Litlamo:

1). Hula li-clamp ka letsoho

2). Li-clamp tsa ho kenya ka letsoho

3. Software ea tlhahlobo ea inthanete

4. Lisebelisoa tsa puisano tsa inthanete

5. Sele ea Sebaka: 2500N

6. Tlhophiso ea Software: Software ea Ts'ebetso ea Taolo ea Boleng (CD-ROM)

7. Li-clamp tse tenyetsehang:

2N--Likhomphutha tse 1

5N--Likhomphutha tse 1

10N--1 Likhomphutha

1)GB/T3923.1---Masela - Ho fumana matla a ho tsikinyeha nakong ea khefu le ho lelefala nakong ea khefu - Mokhoa oa ho qhaqha

2)GB/T3923.2---Masela -- Ho fumana thepa ea ho thaepa ea masela -- Ho fumana matla a ho robeha le ho lelefala ha ho robeha -- Mokhoa oa ho tšoara

3)GB/T3917.2-2009---Thepa ea ho taboha ha masela - Ho fumana matla a ho taboha ha mohlala oa borikhoe (moko o le mong)

4)GB/T3917.3-2009--Masela - Ho fumana matla a ho taboha ha mehlala ea trapezoidal

5)GB/T3917.4-2009---Masela - Thepa ea ho taboha ha mehlala ea puo (sehokelo se habeli) - Ho fumana matla a ho taboha

6)GB/T3917.5-2009---Masela - Thepa ea ho taboha ha masela - Ho fumana matla a ho taboha ha mehlala ea airfoil (moko o le mong)

7)GB/T19976-2005----Masela - Ho fumana matla a ho phatloha - Mokhoa oa bolo

8)FZ/80007.1-2006---Mokhoa oa teko bakeng sa matla a ho hlohlora liaparo ka ho sebelisa lesela le khomaretsang