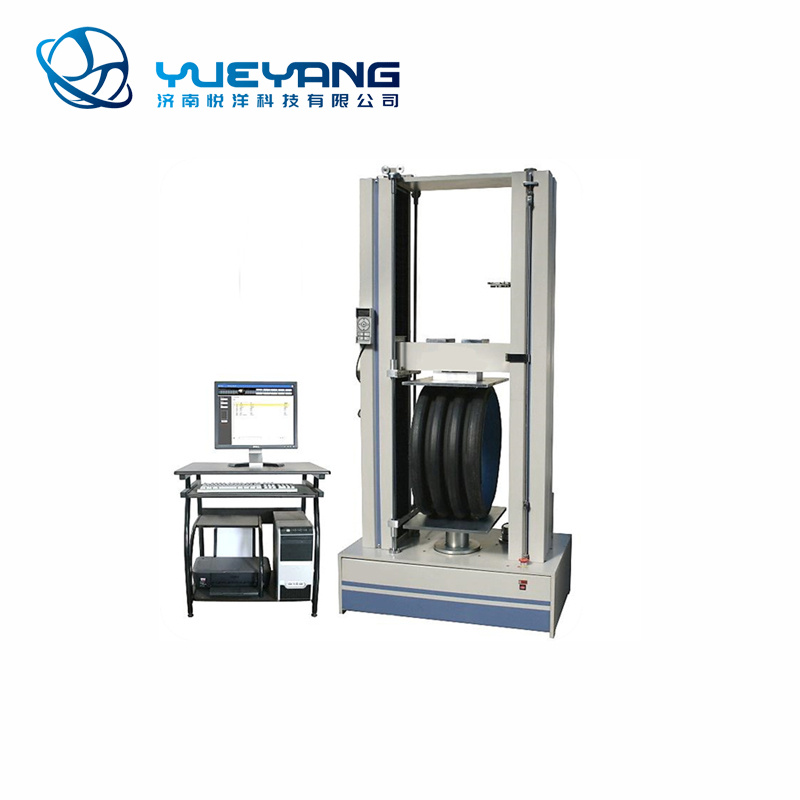

Mochini oa Teko oa Elektroniki oa YYP-WDT-W-60B1

Mochini oa tlhahlobo oa bokahohle oa WDT oa taolo e nyane bakeng sa sebopeho sa kopanyo ea ts'ebetso. O loketse ho tensile, compression, kobeha, elastic modulus, shear, peeling, cracking le liteko tse ling tsa thepa ea mechini tsa mefuta eohle ea (thermosetting, thermoplastic), FRP, tšepe le lisebelisoa tse ling le lihlahisoa. Sistimi ea eona ea software E SEBELISA sebopeho sa WINDOWS (se kopanang le ts'ebeliso ea linaha le libaka tse fapaneng tsa mefuta e mengata ea khatiso ea lipuo), ho latela maemo a naha, maemo a machaba, kapa basebelisi ba nang le tekanyo e tloaelehileng le kahlolo ts'ebetsong e fapaneng, ka polokelo e behiloeng ea liparamente, ho fumana data ea teko, ts'ebetso, tlhahlobo, khatiso ea curve ea ponts'o, ho hatisa tlaleho ea teko, jj. Mochini ona oa tlhahlobo oa letoto o loketse polasetiki ea boenjiniere, polasetiki e fetotsoeng, liprofaele, liphaephe tsa polasetiki le liindasteri tse ling tsa tlhahlobo le tlhahlobo ea thepa. E sebelisoa haholo litsing tsa lipatlisiso tsa mahlale, likolecheng le liunivesithing, mafapheng a tlhahlobo ea boleng, likhoebong tsa tlhahiso.

Karolo ea phetiso ea letoto la mochini oa liteko e amohela sistimi ea servo ea AC ea cha e tsoang kantle ho naha, sistimi ea ho fokotsa lebelo, screw ea bolo e nepahetseng, sebopeho sa foreimi e matla a holimo, ho latela tlhoko e ka khethoa ka sesebelisoa se seholo sa ho lekanya phetoho kapa mithara e nyane ea katoloso ea elektroniki e ka lekanyang phetoho pakeng tsa mola o sebetsang oa sampole ka nepo. Letoto la mechini ea liteko ho ea theknolojing e tsoetseng pele ea sejoale-joale ka ponahalo e le 'ngoe, e ntle, e nepahetseng haholo, e nang le lebelo le pharaletseng, e nang le lerata le tlase, e bonolo ho e sebetsa, e nepahetse ho fihlela boemong ba 0.5, 'me e fana ka mefuta e fapaneng ea litlhaloso/sesebelisoa bakeng sa basebelisi ba fapaneng ho khetha. Letoto lena la lihlahisoa le fumane setifikeiti sa CE sa EU.

GB/T 1040,GB/T 1041,GB/T 8804,GB/T 9341,ISO 7500-1,GB 16491,GB/T 17200,ISO 5893,ASTM,D638,ASTM D695,ASTM D790

| Mohlala | WDT-W-60B1 |

| Sele ea ho Jara | 50KN |

| Lebelo la Teko | 0.01mm/motsotso-500mm/motsotso()E tsoela pele ho sebetsa) |

| Ho nepahala ha Lebelo | 0.1-500mm/motsotso <1%;0.01-0.05mm/motsotso <2% |

| Qeto ea ho falla | 0.001mm |

| Setorouku sa ho falla | 0-1200mm |

| Sebaka se pakeng tsa likholomo tse peli | 490mm |

| Teko ea Teko | 0.2%FS-100%FS |

| Ho nepahala ha sampole ea boleng ba matla | <± 0.5% |

| Kereiti ea ho nepahala | 0.5级 |

| Mokhoa oa Taolo | Taolo ea PC; Tlhahiso ea printa ea 'mala |

| Phepelo ea motlakase | 220V 750W 10A |

| Litekanyo tsa Kantle | 920mm × 620mm × 1850mm |

| Boima bo kahare | 330Kg |

| Dikgetho | Sesebelisoa se seholo sa ho lekanya phetoho, sesebelisoa sa ho lekanya bophara ba ka hare ba phaephe |

Sistimi ea software ea teko e ntlafalitsoe ke k'hamphani ea rona (e nang le litokelo tsa thepa ea kelello tse ikemetseng), mofuta oa lipuo tse ngata ho fihlela litlhoko tsa basebelisi linaheng le libakeng tse fapaneng.

Finyella litekanyetso tsa ISO, JIS, ASTM, DIN, GB le mekhoa e meng ea liteko

Ka ho falla, ho lelefatsa, mojaro, khatello ea maikutlo, khatello le mekhoa e meng ea taolo

Polokelo ea maemo a liteko, liphetho tsa liteko le lintlha tse ling ka boiketsetso

Tekanyo e iketsang ea mojaro le ho lelefatsa

Lehlaseli le lokisitsoe hanyane bakeng sa ho lekola habonolo

Mouse ea taolo ea remoutu le taolo e 'ngoe ea ts'ebetso e fapaneng, e bonolo ho e sebelisa

E na le mosebetsi oa ho sebetsana le sehlopha, e ka ba teko e bonolo le e potlakileng e tsoelang pele

Lehlaseli le khutlela boemong ba lona ba pele ka bohona

Bontša mothapo o matla ka nako ea sebele

A ka khetha mothapo oa teko ea khatello ea maikutlo, ho lelefatsa matla, nako ea matla, nako ea matla

Phetoho ea ho hokahanya ka boiketsetso

Ho beha maemo a holimo le ho bapisa di-curve tsa teko tsa sehlopha se le seng

Tlhahlobo ea keketseho ea sebaka sa teko

Hlahloba lintlha tsa teko ka boiketsetso

Sesebelisoa se seholo sa ho lekanya phetoho

Sebaka se tloaelehileng: mm:10/25/50Phetoho e kholomm:900Ho nepahala (mm):0.001

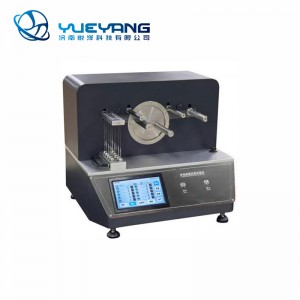

Sesebelisoa sa ho lekanya bophara ba ka hare ba tube