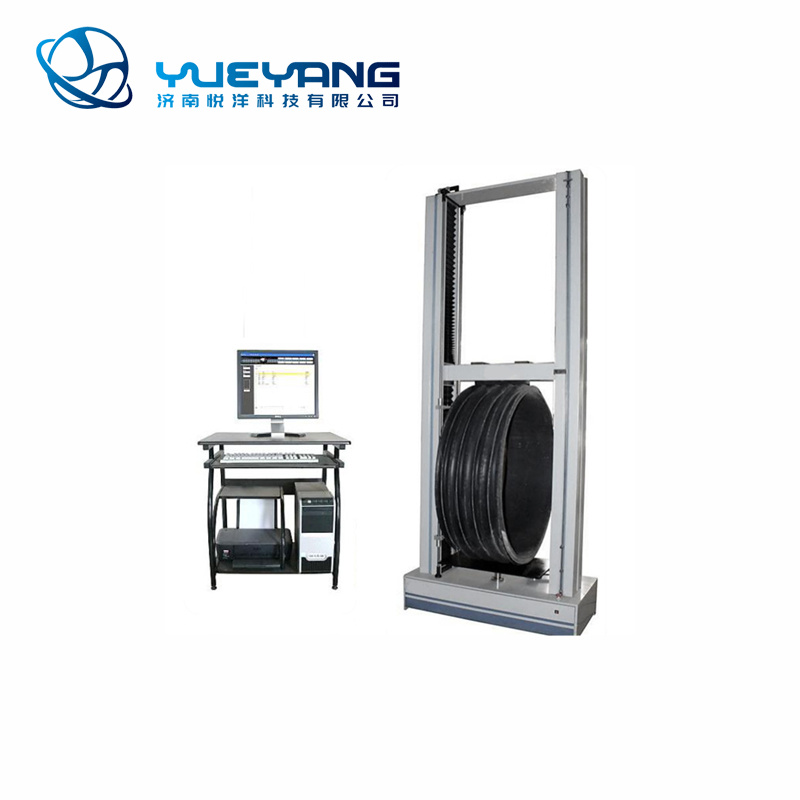

Mochini oa Teko oa YYP-WDT-W-60E1 oa Elektroniki oa Bokahohle (ho tiea ha lesale)

Mochini oa tlhahlobo ea ho thatafala ha lesale o laoloang ka mokhoa o monyenyane oa WDT ke sebopeho sa kopanyo ea ts'ebetso se nang le screw e habeli, moamoheli, taolo, tekanyo, le ts'ebetso. O loketse ho leka litšobotsi tsa mechini tsa liphaephe tse fapaneng tsa polasetiki, liphaephe tse kopaneng le liphaephe tsa FRP, tse kang ho thatafala ha lesale, ho tenyetseha ha lesale, teko ea karolelano ea ho batalla le ho creep, hammoho le teko ea ho tensile ea manonyeletso, ho otlolla terata ea tšepe, ho otlolla strip ea tšepe le tse ling. Ho fihlela litlhoko tsa bellows, liphaephe tse kobehang le litekanyetso tse fapaneng tsa tlhahlobo ea liphaephe tsa polasetiki. Sistimi ea software e amohela sebopeho sa Windows (mefuta e mengata ea lipuo e ka fihlela litlhoko tsa linaha le libaka tse fapaneng), 'me e na le mesebetsi ea ho beha le ho boloka liparamente tsa liteko, ho bokella data ea liteko, ho sebetsana le ho sekaseka data ea liteko, ho bonts'a curve ea khatiso le ho hatisa tlaleho ea liteko, jj. Letoto lena la mechini ea liteko le sebelisoa haholo litsing tsa lipatlisiso tsa saense, likolecheng le liunivesithing, mafapheng a tlhahlobo ea boleng, le likhoebong tsa tlhahiso ea liphaephe.

1. Karolo ea phetiso ea letoto lena la mechini ea liteko e amohela sistimi ea servo ea AC ea brand e tsoang kantle ho naha, sistimi ea ho fokotsa lebelo, screw ea bolo e nepahetseng le sebopeho sa foreimi e matla haholo.

2. Sistimi ea ho lekanya matla a sensor habeli e qoba ka katleho ho thibela ho kheloha ha phaephe e kholo ea caliber, e fokotsa monyetla oa tšenyo ea sensor mme e netefatsa ho nepahala ho hoholo ha teko.

3. Sebetsa 'moho le sistimi e ikhethang ea ho lekanya bophara ba ka hare bakeng sa teko ea ho thatafala ha lesale, tekanyo e tobileng le e nepahetseng haholoanyane, tekanyo e nepahetseng ea liphetoho tsa bophara ba ka hare ba phaephe.

4. Ho ya ka tlhoko ya ho eketsa sesebediswa se seholo sa ho lekanya phetoho bakeng sa ho lelefatsa ho tenyetseha nakong ya teko ya khefu, se ka lekanya phetoho pakeng tsa mela e sebetsang ya sampole ka nepo.

5. Mochini ona o nepahetse ho feta dihlahiswa tse tshwanang tse teng mmarakeng, o na le mefuta e mengata ya tekanyo e potlakileng, ho phaella ho thepa ya mechini ya teko ya phaephe, o ka boela wa sebediswa bakeng sa ho tensile, ho hatella, ho kobeha, modulus ya elastic, ho peel, ho taboha le thepa e meng ya mechini ya teko ya thepa, ka tshebetso e theko e hodimo.

6. Letoto la mechini e lekang theknoloji e tsoetseng pele ea sejoale-joale ka e le 'ngoe, ponahalo e ntle, ho nepahala ho phahameng, lebelo le pharaletseng, lerata le tlase, ho bonolo ho e sebelisa, ho nepahala ho fihlela boemong ba 0.5, le ho fana ka mefuta e fapaneng ea litlhaloso/sesebelisoa sa ts'ebeliso bakeng sa basebelisi ba fapaneng ho khetha.

7. Ka mesebetsi e mengata ea tšireletso e kang ho jara boima ba 'mele, e le hore ts'ebetso ea teko e bolokehe ebile e ka tšeptjoa. Letoto lena la lihlahisoa le fetile setifikeiti sa European CE.

Tumellanong le GB/T 9647, GB/T 18042, ISO 9969 le maemo a fapaneng a teko ea liphaephe, E boetse e fihlela litlhoko tsa GB/T 1040, GB/T 1041, GB/T 8804, GB/T 9341, ISO 7500-1, GB 16491, GB/T 17200, ISO 5893, ASTM D638, ASTM D695, ASTM D790 le maemo a mang.

| Mohlala | YYP-WDT-W-60E1 |

| Teko ea Teko | 1200/3500≤60KN |

| Bophara | Ф3500 |

| Sebaka sa Kholomo | 1200mm |

| Lebelo la Teko | 0.01mm/motsotso-500mm/motsotso()e sebetsa ka ho tsoelang pele) |

| Ho nepahala ha Lebelo | 0.1-500mm/motsotso <1%;0.01-0.05mm/motsotso<2% |

| Qeto ea ho falla | 0.001mm |

| Sebaka sa ho Lekanya Khatello | 0.4%FS-100%FS |

| Mokhoa oa taolo | Taolo ea Khomphutha;Sephetho sa printa ea mebala |

| Phepelo ea motlakase | 220V 750W 10A |

| Tekanyo (mm) | 1280×620×3150 |

| Boima ba 'mele | 550Kg |

| E tloaelehileng | Sesebelisoa sa ho lekanya bophara ba ka hare ba tube |

| Dikgetho | Sesebelisoa se seholo sa ho lekanya phetoho |

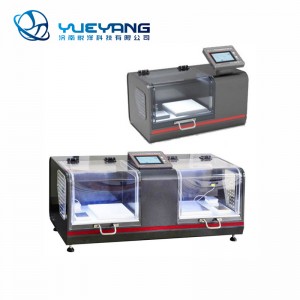

Sistimi ea software ea teko e ntlafalitsoe ke k'hamphani ea rona (e nang le litokelo tsa thepa ea kelello tse ikemetseng), mofuta oa lipuo tse ngata ho fihlela litlhoko tsa basebelisi linaheng le libakeng tse fapaneng.✱ Finyella litekanyetso tsa ISO, JIS, ASTM, DIN, GB le mekhoa e meng ea liteko

✱ Ka ho falla, ho lelefatsa, mojaro, khatello ea maikutlo, khatello le mekhoa e meng ea taolo

✱ Polokelo ea maemo a liteko, liphetho tsa liteko le lintlha tse ling ka boiketsetso

✱ Ho lekanya mojaro le ho lelefatsa ka bohona

✱ü Lehlaseli le lokisitsoe hanyane bakeng sa ho lekola habonolo

✱ Mouse ea taolo ea hole le taolo e 'ngoe ea ts'ebetso e fapaneng, e bonolo ho e sebelisa

✱E na le ts'ebetso ea ho sebetsana le sehlopha, e ka ba bonolo ebile e potlakile ho tsoela pele teko

✱Lehlaseli le khutlela boemong ba lona ba pele ka bohona

✱ Bontša mothapo o matla ka nako ea sebele

✱A ka kgetha mothapo wa teko ya kgatello ya maikutlo, ho lelefatsa matla, nako ya matla, nako ya matla

✱ Phetoho ea ho hokahanya ka boiketsetso

✱Ho beha le ho bapisa di-curve tsa teko tsa sehlopha se le seng

✱ Tlhahlobo ea keketseho ea sebaka sa teko

✱ Hlahloba lintlha tsa teko ka boiketsetso